For centuries, the production methods of refined sugar from sugarcane remained remarkably unchanged. The inefficiencies and expenses of the original methods kept sugar as a rarity; but over a short period around the industrial revolution, mechanization and improvements to the process brought sugar to the people. This pattern of democratization through industrialization occurred in the history of many foodstuffs including chocolate. But of all the changes that occurred during the industrial revolution, the changes in the production of sugar had perhaps the most drastic cultural impact. The new innovations in technology allowed a labor intensive luxury product to become a profitable industry around the world.

Ancient Sugar Production

Sugar production began around 500BC in India. Though there may have been earlier production and certainly earlier cultivation (cultivation of sugarcane has been dated to about 8000 BC), the first methods of sugar production to be recorded came from India in the accounts of Alexander the Great4. During this time, sugar cane was boiled into a sort of syrup, a “taffylike” substance, that could be molded into different shapes3. What we think of as sugar today, a refined crystal, is thought to be a product of Egypt innovation starting in about 400AD4. In the process of making refined sugar, the cane juice was boiled, the excess liquid was evaporated and crystals were formed by “agitating” the remaining liquid3. Lime juice and egg whites were added to the mixture as refining agents and preservatives3. The principles of this simple method survived until the present. However, the scale and tools of production changed as the sugar industry moved to the Atlantic.

Production on the Pre-Industrial Plantations

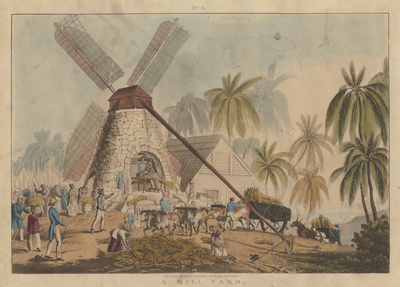

In the European colonies, sugar became a central enterprise with production located on the plantations themselves. On these plantations the sugar was produced by a long, arduous process in mills located on the very plantations that grew the sugar cane. Detailed

descriptions by the plantation owners and operators of the late 1700s give insight into the details of the process. In The Jamaica Planter’s Guide, Thomas Roughley shares his own process6. He details planting and cultivating the cane, cutting the stalks once they were ripe and transporting the cane by mule to the mills6. In the mills the cane was crushed and boiled6. The juices were then sent on to be strained and boiled and tempered by lime juice6. The liquor was then distilled and evaporated multiple times producing sugar crystals. This process was extremely difficult and relied on extensive knowledge by the proprietor6. Roughley describes difficulties with the type of soil, the time of planting and harvesting, the boiling time, the evaporation temperature, and even the weather affecting the outcome of the sugar6. This process was as inefficient as previous methods with high land and fuel costs. It also relied on the inhumane labor practice of slavery. However, early mechanization allowed for increased production. In 1768 steam power was introduced to the Jamaica plantations which allowed the mills to be larger and to run at all hours of the day (at the expense of the slave labor required to operate the mill)3. It also allowed more heat to be generated in the boiling and evaporation process3. The implementation of this new steam technology marked a turning point in sugar processing. During the coming Industrial Revolution and in the years following the introduction of steam, a process that had largely been the same for 1000 or more years rapidly became mechanized and produce larger quantities of sugar than had ever been seen before.

The Industrial Revolution

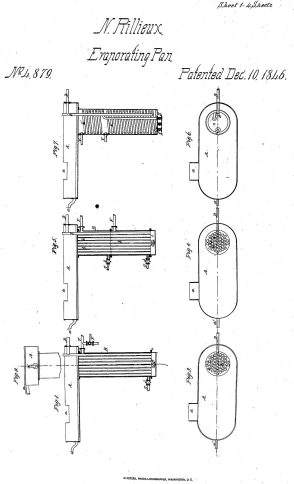

Over the next two centuries from the time of the Jamaica plantations to the present, several new inventions changed the sugar making process to make it more productive and efficient. The first change included boiling the cane juice in a closed container, rather than an open cauldron3. This required less heat thereby reducing the risk of carmelization and lowering fuel costs3. The most important revolution came in 1846 when Norbert Rillieux

invented the evaporator5. This new device used multiple pans at different pressures to evaporate the liquid from the sugar in a very efficient and controlled environment5. The final major improvement to the process during the Industrial revolution came in 1852 with the invention of the centrifuge, which allowed sugar crystals to be separated from molasses3. In a matter of less than 100 years these inventions turned a slow, inefficient process that had been used for thousands of years into a mechanized process that produced significantly greater quantities and quality of sugar.

Modern Sugar Processing

Today sugar is made using the inventions of the Industrial Revolution and the basic methods of boiling and evaporation developed in India over 2000 years ago. The Imperial Sugar Company gives an insight into this modern method in this video2. We can see not only how the use of machines has changed the process, but also the ways in which the basic tenets remain unchanged. The consequences of the development in the production methods of sugar cannot be understated. The change in production methods played a vital role in sugar’s journey from a rarity to a luxury, to a commonly eaten food, to a necessity in the western diet. With mechanization came mass production, which helped to decrease the price of cane sugar and increase the supply4. This price decrease along with a myriad of other social and cultural factors helped make sugar accessible to all classes and turned sugar into the central carbohydrate of the modern world4.